Are you looking for a customised pump for your business? Our long experience with pumps means that we have the capacity to customise an eccentric screw pump exactly as you want it.

With MAF Pump you get:

- customised pumps for your needs

- a drawing of the pump that you approve

- Swedish manufacturing

- fast delivery times

- lower costs

- training and start-up of the pump on site.

We can customise an eccentric screw pump to your business. This way we can offer the most efficient solution for the technical system or process. We provide you with advice and support from concept to installation. Get in touch with us and we will help you.

Manufacture of customised pump in own workshop

30 years of experience makes MAF Pump your competent full-service supplier of customised pumps. Our customised solutions are used in industrial processes all over the world - from wastewater treatment plants, manufacturers, paper and pulp industries to slaughterhouses. In our own workshop in Mölndal, we offer welding, turning, painting and blasting, as well as service technicians with great knowledge and personal commitment.

Swedish-made pumps

Our progressive cavity pumps are manufactured in Sweden, and each pump is a customised solution that creates unique opportunities for our customers. With an individual ID number, we guarantee full traceability and quality, allowing you to rely on our products for your specific needs.

CAD technology provides customised pumps with optimal performance

Eccentric screw pump with reversible flow or customised trough pump? Together with you, we go through what type of pump design you want and what your needs are. We then produce 3D drawings in the CAD programme Inventor, where we adapt and update the drawing until the design has been approved. The next step is the manufacture of the customised pump in the workshop, where we have full control over the entire process.

In addition to complete technical documentation, we also offer pump-on-site packages where we deliver the customised pump to you, perform installation and commission it. You will also receive on-site training in the operation of the pump from our skilled technicians, to ensure a high-performance and long-term solution.

Do you want to equip the progressive cavity pump with a clamping sleeve?

Our progressive cavity pumps with clamping jacket provides an increased lifetime for both the stator and the rotor. All our models have smooth and quiet operation. BA models are ideal for special constructions with viscous or abrasive media, for example:

- wastewater treatment plant

- food establishments

- paper & pulp

- chemical industry

- mines.

The stator, lubricating oil and rubber parts are approved for food handling and the pump is easy to clean on site. The suction head is up to 7 mvp and the pump has a capacity for flows up to 150 m3/h.

Examples of our specialised pumps

Customised pump for silo

Firstly, the bottom plate has been adapted to fit exactly in the available space and at the same time made stable for reliable operation. The trough has a large round intake to fit the existing silo outlet.

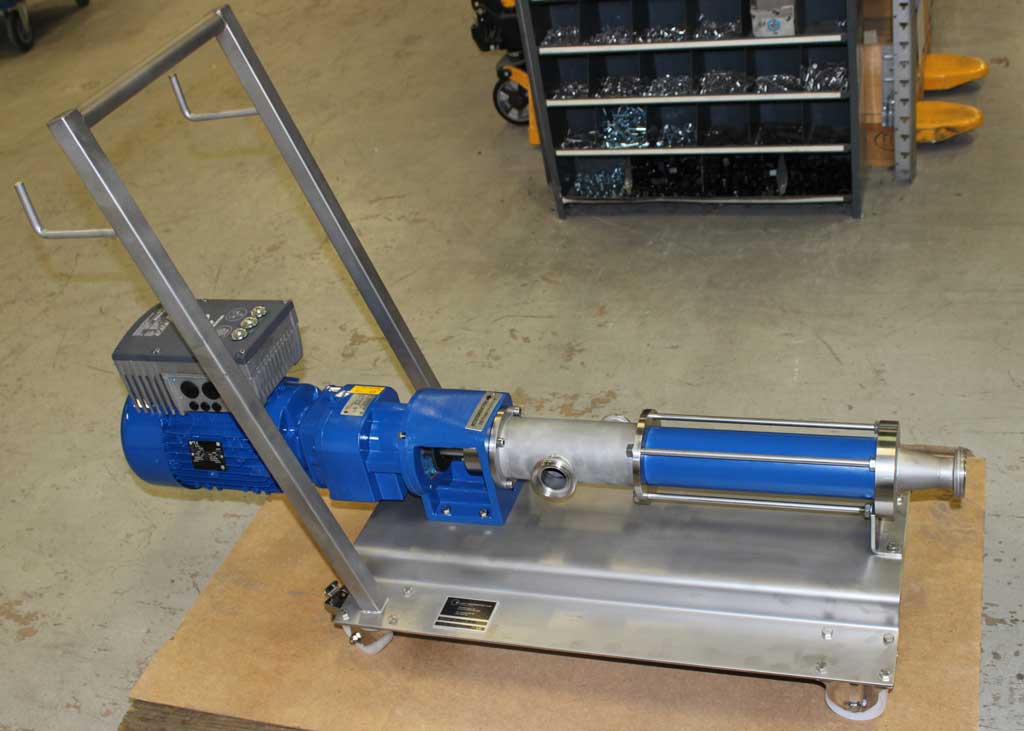

Specialised mobile pump for rapid movement

This pump needed to be moved quickly to different stations to pump for short periods. The pump is mounted on a trolley with wheels and handles for easy movement.

Specialised pump for the production of animal feed

Here we were asked if we can develop a pump that can be hung upside down to pump up liquid animal feed from the bottom of a tank.

Do you have any questions about our pumps? Contact one of our sales representatives and we will help you!

Product catalogue

Related business areas

Our models

MODEL BA

Standard pump for municipal and industrial applications.

MODEL BC

Trough pump with auger feeder. The trough is shown in a separable version.

MODEL DP

Dosing pump for small flows with high precision.

MODEL FG

Food pump with Clean In Place connections.

MODEL SE201BA

One pump for all types of media.

MODEL SE202BC

Trough pump with screw conveyor. All in acid-proof material.

MODEL SE551BA

Equipped with clamping jacket for increased rotor and stator lifetime

MODEL SE1452BC

With painted trough is suitable for dry sludge.

Specialised pumps

Service & Spare parts

We service most makes of progressive cavity pumps and as the only Swedish dealer of Vaughan chopper pumps and Volute sludge dewatering equipment, we also service these products. Thanks to our large stock of spare parts, we can ensure fast deliveries at the best quality.

Our service technicians have extensive experience. We carry out everything from preventive maintenance to all types of pump rebuilds, such as changing from stuffing box to mechanical shaft seal. We are good at customised special solutions and can, for example, adapt pump housings and feed screws to adapt operation to different customer needs.